At the beginning of the summer in 2022, Target made a surprising announcement: it was about to run a sale so large, it needed to issue a warning to its shareholders that the company was going to take a planned financial hit as a result.

Why in the world would a company sell goods below cost? In Target's case, it's because their warehouses were overloaded with unsold inventory left over from pandemic-driven demand for things like activewear and house clothes. Once people's buying habits were back to (mostly) normal, the company was stuck with more sweatpants than it knew what to do with. (Which means I now own more sweatpants than I know what to do with.)

It's a rare thing to behold, thanks mainly to a process that companies use called "sales and operations planning," or S&OP. Through the S&OP process, companies are able to predict how much product they'll need to meet future demand. Provided there's not an unforeseeable global crisis to contend with, S&OP forecasting is usually pretty accurate.

What is S&OP?

Sales and operations planning, or S&OP, is a process that businesses use to ensure they have the right amount of inventory—not too much (like Target) and not too little (which would cause them to miss out on potential sales).

The S&OP process is cyclical and is repeated either monthly or quarterly, depending on how far into the future the company is able to forecast. Companies whose products are always in demand and don't expire—like, say, alcohol—can afford to do their sales and operations planning less frequently. Seasonal, perishable, or highly trend-specific products require more careful sales and operations planning.

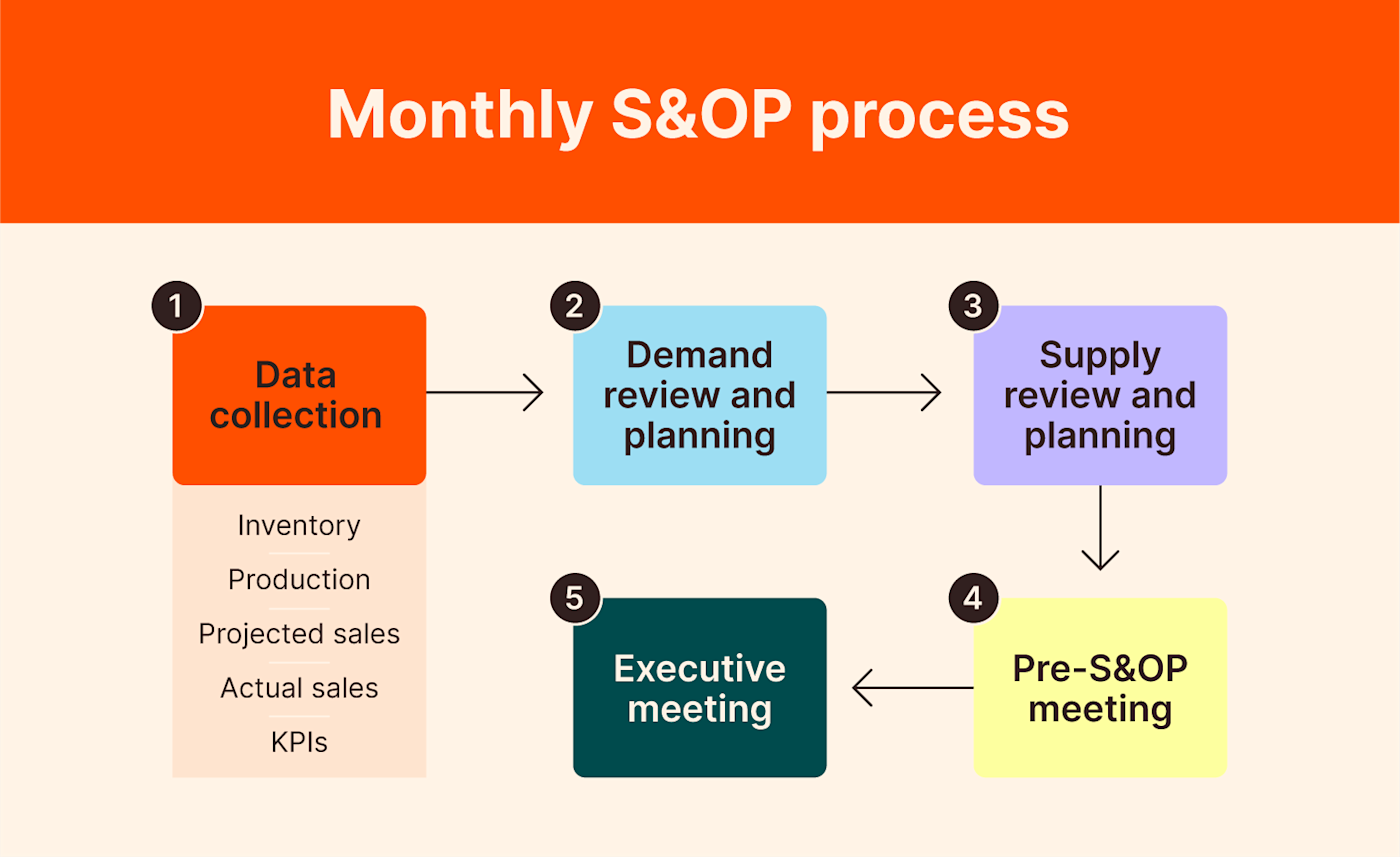

The S&OP cycle is ongoing and restarts at the end of every period, beginning with the collection of the past month's sales data and ending with an executive meeting where the company decides what its sales plan is for the coming period.

5 steps of the S&OP process

There are five different steps, or phases, to sales and operations planning. They are:

- Data collection

-

Demand planning

-

Supply planning

-

Pre-S&OP meeting

-

Executive meeting

Here we'll dive into each step in more detail and explain what goes on in every phase. For the purposes of this explanation, I'm going to use the word "month," but the steps and process are the same no matter what time period you choose to work with.

Step 1: Data collection

The first step in the S&OP process is to collect data from the prior month that can help you identify supply and demand patterns and plan production going forward. Key data to collect from the previous month includes:

-

Projected demand

-

Actual sales

-

Inventory produced

-

Production capacity

-

Events impacting demand (market shifts, price changes, or real-world events)

You'll also need to reference some of your standard financial information during this process, so you'll want to make sure you have the most recent and updated numbers for:

-

Production costs

-

Product price

-

Holding costs

-

Shipping/transportation costs

With this data in hand, you can move on to the next step: demand planning and review.

Step 2: Demand review and planning

The next step in the process is to evaluate demand levels, both for the prior month and historically over time. During this review, you should look to answer these questions:

-

What did we predict that demand would be last month? Did actual demand sales reflect these predictions? If not, why?

-

Did demand fluctuate in ways we didn't anticipate? What caused these fluctuations?

-

How did last month's demand compare to demand for the same month last year and years prior? What patterns are consistent year-to-year?

-

What wider market trends are influencing our market sector right now? Are there global events at play that may impact demand?

The goal of a demand review is to use historical data to figure out what events, patterns, and trends are influencing sales. Then, you'll use that information to create a forecast predicting demand levels for the coming month.

Step 3: Supply review and planning

I say this is step three, but supply and demand planning can usually happen simultaneously. In this step, you'll repeat the same steps you used in the demand review, but with a focus on the supply side. This time, you'll start with one main question: how much inventory did we produce last month to meet our predicted demand, and was it enough or too much?

The questions you ask from there will depend on whether you had a surplus or shortage of supply.

If you overproduced last month:

-

Why was supply higher than forecasted? Were there mistakes in last month's forecasting process?

-

How much unsold product is being stored in inventory?

-

Is your product perishable? What's the cost of your waste?

-

Are the products highly seasonal, or will there be demand for them in the coming month?

-

What are your holding costs? (In other words, how much does it cost you to store this inventory?) Does it make more financial sense to store it or sell it at a discount?

If you had a shortage last month:

-

Why did your supply forecast fall short of actual sales? Were there mistakes in last month's forecasting process?

-

Was the shortage caused by a shortage of materials needed to create your product? If so, is that shortage still in effect?

-

Do you have the necessary materials to produce enough goods to meet higher demand in the coming month?

-

What is the cost per unit of production? Are there materials or process changes you can make to lower your production costs?

You should also evaluate wider economic trends to determine whether there are external factors that could affect your ability to meet demand. For example, if you rely on commodities like oil, gas, wood, or water, you'll need to stay aware of environmental and political factors that could affect your supply chain.

Once your supply review is completed, you'll move on to supply planning. What this part of the process looks like will vary a lot depending on what kind of business you're in. Ultimately, you want to come up with different potential scenarios for the coming month and determine how best to meet demand while minimizing costs.

Step 4: Pre-S&OP—reconciliation of plans

After supply and demand planning are complete, you enter the "pre-S&OP" meeting stage. Depending on your business's size and process, this can be multiple meetings with different departments, or it can be one large gathering. The goal is to connect your supply and demand plans with all of the other departments in your company, like finance, product, customer service, and marketing.

Let's say your forecasts predict higher demand next month and therefore higher required supply. Different departments will be affected in different ways:

-

The finance department will have to draw up a plan to source more materials and divert higher profits to the appropriate departments.

-

Customer service will need to adjust schedules to ensure full coverage through peak sales times.

-

If you're having a sale to clear out out-of-season inventory, the marketing department will need to plan an ad push.

Every department in the company will be affected by supply and demand forecasts, and your supply and demand plans will be affected by every department in the company. Since the plan will continue to evolve as you reconcile it with each department, the most efficient way to manage pre-S&OP reconciliation is with a shared dashboard and centralized workflow plan. Set up automations to notify stakeholders when plans change, new information is needed, or another meeting is put on the books.

Step 5: Executive meeting—finalize S&OP

When your S&OP plan has been reconciled with and approved by each department, it moves on to the last step: the executive S&OP meeting. This is where the company's senior leaders come together to review the S&OP plan and make any necessary adjustments. The goal of this meeting is to ensure that the plan is realistic and achievable, and that it aligns with the company's overall strategy.

As soon as the executive team signs off on the S&OP plan, the entire company can get to work putting it into action. This is another area where automation can be handy—each department leader can set up the first steps of their process to be triggered by the executive S&OP approval. For example, the marketing team might have a drip email campaign ready to go, or the sourcing and procurement department can trigger automatic RFP submissions. Since the S&OP process starts over as soon as the last cycle ends, automations are key to making sure that nothing falls behind.

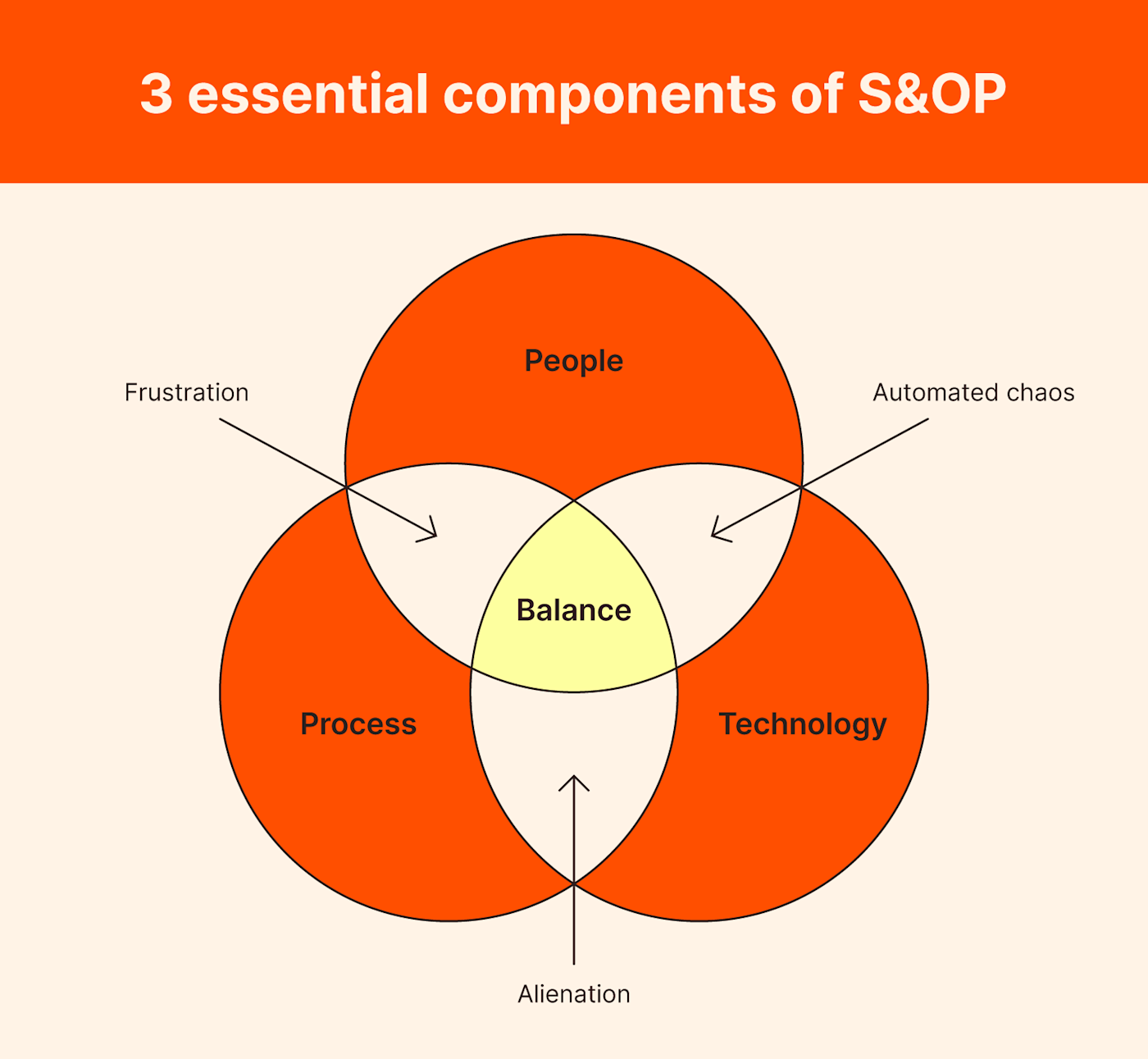

3 components of S&OP

The entire S&OP process relies on equal involvement of three key components: people, process, and technology. If any one of these components is missing or out of balance, the S&OP process falls apart.

People

The pre-S&OP reconciliation process can feel a bit like herding cats. You reconciled the plan with finance last week, but this week's marketing meeting resulted in changes that make last week's sign-offs moot. Getting everything to line up perfectly can be so difficult that some teams are tempted to skip the process and just handle it themselves.

Here's the problem: you don't just need logistics buy-in. You need the support and approval of your department stakeholders in order to execute your S&OP plan well. When you don't involve your people in the process, you wind up with an alienated, disengaged workforce.

Process

The steps of the S&OP process aren't as cut and dry as your regular checklist of to-dos. The process is ongoing and repeats as soon as it's complete, and different phases can overlap as parts are delegated to different team members. With these semi-blurred lines separating your process steps, it's easy to lose your structure entirely, which will bring the whole operation down quickly.

A well-structured process is necessary to keep your S&OP cycle flowing smoothly. Automation can help with a lot of that, allowing you to offload repeatable tasks to technology and focus on the work that most requires your attention. But if you have people and technology without a process, you wind up with automated chaos. There's a reason that automations aren't designed to replace people—they require structured oversight to work effectively.

Technology

There are lots of things that are made easier by technology but would be perfectly doable without. The S&OP process is not one of those things. Unless you're running a very, very small operation, trying to do your S&OP by hand will be very frustrating indeed.

Without technology, S&OP teams would have to collect and process data by hand, create forecasts manually, and personally implement their plans once they're approved by the executive team. With automated systems, you can collect data on an ongoing basis, generate reports with multiple views and time frames, set up implementation triggers, and communicate instantaneously with your team.

S&OP software and automation

In theory, you could manage S&OP with a patchwork of other apps and platforms to handle different parts of the process. In reality: that way lies frustration and disaster. This is one area where, unless you're running a small operation, a purpose-built S&OP platform really is a necessity.

There are lots of S&OP platforms out there, like SAP, Oracle, Vanguard, Logility, and Atlas. Each platform offers different features, but all S&OP software will include some basic capabilities:

-

Data collection

-

KPI tracking

-

Reports and analysis

-

Collaborative planning tools

-

Forecast calculations

-

Scenario planning

You might be able to handle collaboration via your project management tool or track sales and inventory with a spreadsheet (up to a point), but an S&OP platform works cross-functionally so that all of these processes are managed in one place. When you update a figure—say, a warehouse floods and 10% of your inventory is lost—your entire S&OP process, from data reports to scenario forecasts, will update automatically.

When choosing an S&OP platform, pay attention to app integrations and compatibility. You'll want your software to be able to do things like pull sales and inventory data from your CRM, send pricing updates to your accounting system, and notify your team with updates. The more of your S&OP process you can automate, the more time you'll have to connect with your team, make complex operations decisions, and stay ahead of any supply and demand curveballs headed your way.